Views: 98

Among the most effective techniques for the management of complex projects we find the Critical Path Method (CPM) and theEarned Value Management (EVM).

In this article we will not focus on the technical definitions of these two methodologies (already deepened in other contents), but we will analyze their synergy and critical issues that can emerge if applied in an misaligned way.

Introduction

- Introduction

- Because it is important to identify the critical path in the field of project management?

- Bases of the EVM methodology

- Integrated application of CPM and EVM

- The need for congruence between the two techniques

- The detection of physical advancement

- The problem

- A real case

- Analysis of the combinations of TF and SPI

- Considerations on advancement reports

- How to avoid distortions between the Enedned Value metrics and the reticular program

- The use of Credit Manhours

- Find out how to master EVM methodologies!

- Discover the complete course of project management and control!

The uncertainty on times and costs is an intrinsic feature of each project. To face it effectively, It is necessary to have not only reliable techniques, but also of one integrated vision management. The Project Management moderno It is not limited to the correct application of individual techniques, but requires the development of a system capable of integrating tools, processes, Organization and corporate culture. Only through this integration is it possible to guarantee the success of the project

Because it is important to identify the critical path in the field of project management?

Identifying and monitoring the critical path is one of the central duties of the project manager.

In complex projects, The only initial planning is not enough: It is necessary to constantly check the activities that determine the total duration of the project, per promptly direct resources e prevent delays.

The CPM, developed already in the 1950s for military projects, responds to this need with precision and rigor.

Bases of the EVM methodology

L’Earned Value Management (EVM) It is now recognized as one of the most advanced tools for integrated time control, Costs and performances.

It is not limited to photographing the progress of the project, But it allows you to evaluate performance in an objective way and anticipate any critical issues, providing the project manager with the necessary elements for timely action.

Originally developed in the 1960s for US defense programs, The EVM methodology was formalized as the standard Ansi 748 In the 1998 and subsequently recognized internationally with the standard ISO 21508:2018.

What the EVM distinguishes from other tools is his ability to integrate information on time, cost and physical advancement, creating a direct connection between the programming (schedule) and the measurement of performance.

This integration makes EVM a real Methodological infrastructure for the project control, which can be adopted at different levels of maturity and complexity, Based on the company or project context.

Integrated application of CPM and EVM

In many business contexts, il CPM It is used to build and update the work program, Mentre l ’EVM it is used to measure performance in terms of times and costs.

The integration between these two techniques allows you to create a advanced control system, capable not only of representing the plan, but also of evaluate the effectiveness of its execution.

However, so that this integration produces reliable results, It is necessary to guarantee the consistency between the temporal logic of the program and the progress of the progress.

This is one of the most delicate aspects of the application of the AVM on CPM bases.

The need for congruence between the two techniques

The congruence between CPM and EVM It is a necessary condition to ensure the reliability of the control data.

In many cases, The EVM is implemented downstream of a CPM program built in the initial phase and updated with variable frequency. However, If the advancement data are not entered in a coherent way compared to the logic of the program, The indicators produced by the AVM may be misleading.

For example, It may happen that an activity is technically late according to the CPM network, but that is reported as "advanced" for administrative or contractual needs. In this case, The SPI index (Schedule Performance Index) could return a deceptive value, masking the real delay.

For this reason, The project manager must make sure that The detection of physical advancement is aligned with the temporal logic of the program and that the update process is governed by clear and shared rules within the project team.

The detection of physical advancement

To ensure the effectiveness of the AVM, It is essential that the measurement of physical advancement of activities are as close as possible to the executive reality of the project.

This measurement must not be limited to subjective estimates or percentages of arbitrary completion, but it should be based on objective and verifiable parameters, defined in the planning phase.

Only in this way can the AVM indicators correctly reflect the actual state of the project, avoiding discrepancies between the logical plan (CPM) and the control data (EV, PV, AC).

The problem

When the detection of physical advance is not based on objective and consistent criteria with the CPM program, The data that feed the EVM forgive meaning.

In many projects there is a tendency to declare "formal" progress percentages, often influenced by administrative needs or by contractual pressures. This behavior produces a distorting effect: The performance indices of the AVM appear correct or even positive, while the project is late according to the logic of the program.

The discrepancy between what the CPM reticulum indicates as a critical path and what is reported in the EVM system risks generating an altered perception of the real situation. Consequentially, Management could take decisions based on only apparently reliable information.

A real case

The first time I faced a situation of this type was in the construction of a two -lane viaduct, part of an important road infrastructure, that crossed a river. The Baseline program provided that, After building the batteries on a bank, we proceed with those on the other side.

This approach was necessary to allow the transit of the necessary equipment to the launch of the beams. To simplify, Suppose that the program expected this construction sequence:

- Pila for a lane on the first bank from the Pulvino foundation poles – cross beam -.

- Corresponding pile on the opposite quay.

- Same process for the second lane.

Ma, contrary to the program, The construction site management decided to simultaneously also create the pile of the other via del viaduct, Since all the equipment was already available on site. This choice, apparently logical from an operational point of view, involved an alteration of the execution expected in Baseline.

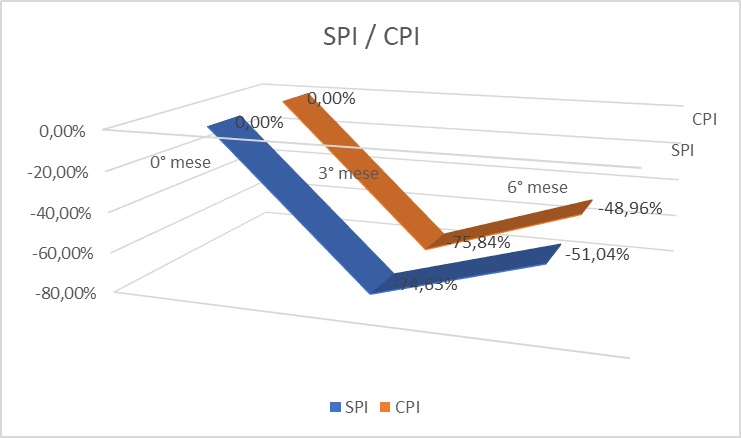

At the end of the period, However, two batteries were completed. The SPI index would not report any deviation, because the volume of work planned (production) had been respected. However, The reality is that this choice had caused a delay on the critical path, that the SPI only had not been able to highlight.

Analysis of the combinations of TF and SPI

To correctly evaluate the progress of the project, You can use the following control panel (Source: Jelen’s Cost and Optimization Engineering – Sponsored by AACE) which relates the value of the SPI index with the value of the total float (TF):

| Total Float (TF) | SPI > 1.0 | SPI = 1.0 | SPI < 1.0 |

| TF > 0 (Available time) | In anticipo sul critical path; More work performed than what is planned. | In anticipo sul critical path; lack of work on non -critical activities. | In anticipo sul critical path; significant work deficiency on non -critical activities. |

| TF = 0 (Critical path respected) | Critical Path in the time; More work performed on non -critical activities than planned. | Critical path on time; Total work volume in accordance with planning. | Critical path on time; lack of work on non -critical activities. |

| TF < 0 (Delay on the critical path) | Activities of the late critical course; higher overall work volume than expected, indicating excessive attention to non -critical activities. | Activities of the late critical course; Total work volume in accordance with planning, but with too much attention to non -critical activities. | Activities of the Critical Path late; overall work volume lower than expected; a greater overall effort is needed. |

Considerations on advancement reports

The publication of advancement reports showing SPI values > 1, In the presence of activities outside sequence, It can generate misunderstandings and a false sense of safety. The incorrect perception that "the important thing is production" risks hiding real delays on the Critical Paths.

Furthermore, When the activities outside sequence occur frequently, The Project Controls Manager/Engineer is forced to a demanding job to explain, case by case, the real situation.

However, also with detailed and attentive reports, The risk of distorted information or misunderstandings about the progress of the project remains high, Unless adequate metrics are adopted.

How to avoid distortions between the Enedned Value metrics and the reticular program

There are Cost Engineering techniques that allow you to mitigate the Distortions in EV metrics and that must be integrated both in the contractual clauses and in procedure di Project Controls. The main strategies are two:

- Baseline performance definition.

- It must be built using the "Late" dates instead of the "Early" dates.

- Progress registration criteria (progress tracking).

- The progress that contributes to the value of the SPI must be recorded only in the period in which the activity was actually planned (I.E., to Float consumed), unless the activity in question is part of the current critical path.

Following this approach, SPI values > 1 they will only occur when critical activities are actually anticipated, that is, the only scenario in which a real advance of the project timing is possible.

The use of Credit Manhours

Another advanced Cost Engineering technique, Less known but extremely useful, it concerns the concept of Credit Manhours.

This approach is not directly connected to the SPI index, But rather at the Cost Performance Index (CPI), that measures efficiency in the use of resources.

An example of application:

- The CPI is calculated as EV/AC (Earned Value diviso per Actual Cost).

- Instead of using the Ened Hours parameter, Credit Hours are adopted, which allow you to monitor productivity independently of the budget variations.

Credit Manhours allow you to obtain a coherent production index even in case of variations in the budget, resulting particularly useful in complex projects.

The role of the project manager

Ensure the consistency between works program (CPM) and performance measurement (EVM) It is not just a technical question, but a real management responsibility.

The project manager must promote a culture of control based on reliable data, define objective criteria for the detection of advancement and ensure that information flows are consistent between planning and reporting.

Only in this way can EVM express all its potential: Not as a simple numerical dashboard, But how integrated decision -making tool, capable of guiding the project towards the objectives of time, cost and quality.

🔗 You want to deepen the CPM techniques, Pert and EVM in an operational key?

Read the article: “Project Management methodologies for success: PERT, CPM, EVM”.